A practical guide to understanding how Just-in-Time (JIT) helps businesses reduce excess inventory, improve efficiency, and increase profitability.

What Is Just-in-Time (JIT)?

Just-in-Time (JIT) is an inventory management strategy where materials and products are purchased or produced only when they are needed.

Instead of storing large quantities of stock for future demand, businesses align purchasing and production with actual customer requirements.

In simple terms:

- Buy what is needed.

- When it is needed.

- In the quantity required.

This reduces unnecessary storage and lowers inventory costs.

Why Inventory Control Matters

For many Indian MSMEs, a significant portion of working capital is locked in unsold stock. Warehousing costs increase, products become outdated, and cash flow becomes tight.

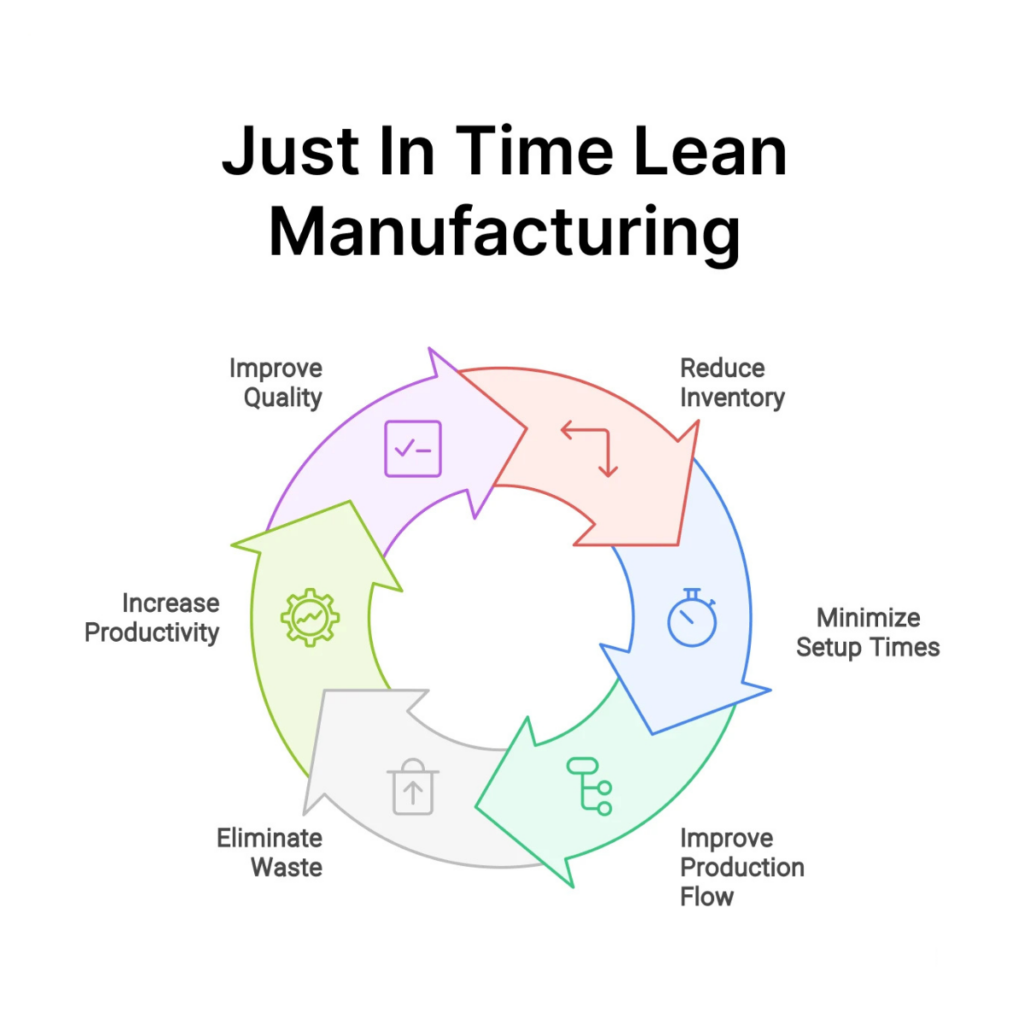

Just-in-Time (JIT) helps businesses:

- Reduce storage expenses

- Free up working capital

- Minimize waste

- Improve operational efficiency

- Strengthen cash flow

When capital is not blocked in inventory, it can be used for expansion and growth.

The Core Principle Behind the Strategy

The main idea behind Just-in-Time (JIT) is demand-based production and purchasing.

Businesses respond to real customer orders instead of predicting demand too far in advance. This creates lean operations and improves cost control.

However, successful implementation requires strong coordination between suppliers, production teams, and sales departments.

Example: Manufacturing Business

Imagine a small machinery parts manufacturer.

Traditional method:

- Buy raw materials in bulk

- Store them for long periods

- Risk damage or obsolescence

With Just-in-Time (JIT):

- Order materials according to production schedules

- Receive supplies close to manufacturing time

- Reduce storage and handling costs

This improves space utilization and reduces financial pressure.

Example: Retail Sector

Retail businesses often struggle with excess seasonal inventory.

By applying Just-in-Time (JIT), retailers can:

- Order smaller quantities

- Reorder based on actual sales data

- Avoid heavy discounts due to unsold stock

This protects profit margins and improves inventory turnover.

Key Benefits

When implemented correctly, Just-in-Time (JIT) provides:

- Lower inventory holding costs

- Improved liquidity

- Reduced product waste

- Faster response to demand changes

- Better supplier coordination

For growing companies, this approach supports financial stability and operational discipline.

Requirements for Success

This system works best when businesses have:

- Reliable suppliers

- Accurate demand forecasting

- Efficient communication

- Proper inventory tracking

- Stable production processes

Without these factors, supply delays may interrupt operations.

That is why Just-in-Time (JIT) requires careful planning and strong supplier relationships.

Risks and Challenges

While effective, Just-in-Time (JIT) also carries certain risks:

- Supplier delays

- Transportation disruptions

- Unexpected demand spikes

- Overdependence on limited vendors

Businesses must evaluate these risks before adopting the strategy fully. In some cases, maintaining limited safety stock may be necessary.

When Should Businesses Use It?

This strategy is especially useful when:

- Inventory costs are high

- Storage space is limited

- Demand is relatively stable

- Suppliers are dependable

- Cash flow improvement is required

Just-in-Time (JIT) performs best in predictable and well-managed environments.

Common Mistakes to Avoid

Some companies reduce effectiveness by:

- Choosing unreliable suppliers

- Ignoring demand patterns

- Eliminating buffer stock without analysis

- Failing to monitor supplier performance

Proper implementation of Just-in-Time (JIT) requires ongoing evaluation and adjustment.

How It Supports Business Growth

Efficient inventory management directly improves profitability. Lower storage costs increase margins, and better cash flow allows reinvestment into the business.

Just-in-Time (JIT) encourages lean thinking across operations. It strengthens supplier partnerships and promotes disciplined planning.

For Indian businesses aiming to scale sustainably, inventory efficiency can become a strong competitive advantage.

Conclusion

Just-in-Time (JIT) is a smart and practical inventory strategy that reduces waste and improves operational efficiency.

In competitive markets, holding excess stock increases risk and reduces profit. Just-in-Time helps businesses operate lean while maintaining service quality.

When managed carefully, this approach transforms inventory from a financial burden into a strategic strength.

Businesses that implement JIT effectively build stronger cash flow, better cost control, and sustainable growth.

Image Credits: 6 Sigma

For more articles on startup growth, fundraising strategies, and business insights for Indian founders,

visit: Udyamee India Magazine