Why surface-level fixes keep failing, and how smart Indian businesses use Five Whys Analysis to find the real cause, save money, and build stronger operations.

What Is Five Whys Analysis?

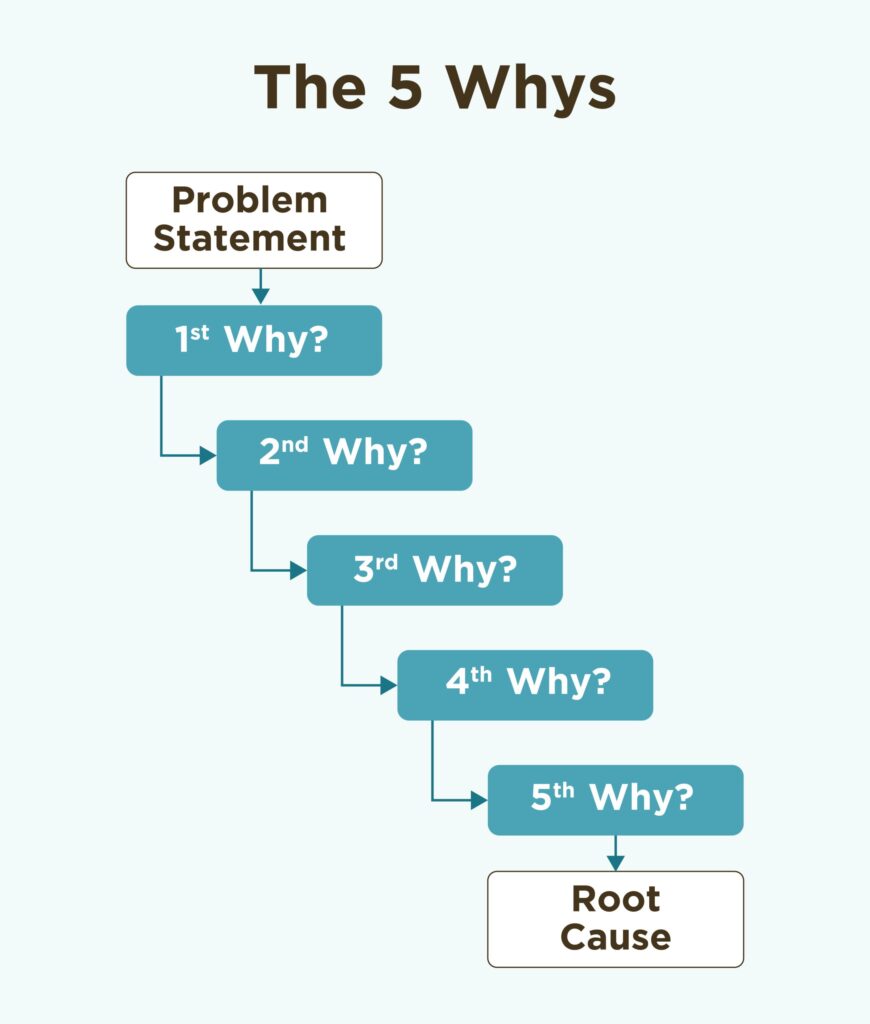

Five Whys Analysis is a structured problem-solving method that helps you find the real reason behind a problem instead of just treating its symptoms.

Think of it this way: if your production line keeps stopping, you can keep restarting it manually. But if the real issue is an overloaded circuit with no load-balancing system, the problem will never go away until you fix it properly.

The same logic applies to every kind of business problem.

Five Whys Analysis asks you to keep asking one powerful question until you reach the truth:

- What happened?

- Why did it happen?

- Why did that happen?

- Why did that happen?

- What is the real system failure behind it all?

Most businesses fix problems on the surface. The complaint stops. The fire is put out. Everyone moves on. But weeks later, the same issue returns, sometimes worse.

Without Five Whys Analysis, you are stuck in an endless cycle of firefighting.

Why Five Whys Analysis Matters for Indian Businesses

Whether you run a manufacturing unit, a service company, or a retail shop, Five Whys Analysis delivers real value:

- Eliminates repeated failures — Solve problems once, properly.

- Saves money — Stop wasting resources on the same issue again and again.

- Improves quality — Better products and services build customer trust.

- Strengthens systems — Your processes become more reliable over time.

- Supports ISO compliance — Quality management systems require corrective action, and Five Whys Analysis is the foundation many businesses build on.

The difference between struggling businesses and successful ones often comes down to this, do they fix symptoms, or do they fix real underlying causes?

The Core Principle

Every problem has a cause. If you remove the root cause, the problem will not return.

Consider this example:

Problem: Customers are receiving damaged products.

Temporary fix: Replace the item and apologise.

Deeper approach with Five Whys Analysis:

- Why is the product getting damaged? Packaging is breaking during transit.

- Why is packaging breaking? The material used is too weak.

- Why was weak material selected? No transit stress test was ever done.

- Why was no test done? No quality check process exists before dispatch.

- Why does no process exist? Nobody was ever assigned this responsibility.

Once you fix the true cause, whether it is packaging standards, inspection process, or staff responsibility, damage complaints drop permanently.

That is the power of asking deeper questions.

How to Run Five Whys Analysis in Your Business

The method is simple and requires no expensive tools or outside consultants.

- Step one — Write down the problem clearly. One sentence. A vague problem gives vague answers.

- Step two — Gather the right people. Include those who actually do the work. They know what is really happening on the ground.

- Step three — Ask “Why?” and write the honest answer. Then ask “Why?” again. Keep going until you reach something fixable, a missing process, a training gap, or an unclear responsibility.

- Step four — Take real action. Assign someone, set a deadline, and follow up. Five Whys Analysis is only as powerful as the action that follows it.

A Real Example from India

A textile manufacturing unit in Surat was facing repeated machine breakdowns every few weeks. Production was getting delayed and customers were complaining. Management kept blaming the maintenance staff.

Instead of punishing people, they sat together and ran Five Whys Analysis:

- Why did the machine break down? The motor overheated.

- Why did it overheat? The bearing was not lubricated.

- Why was it not lubricated? Maintenance was skipped.

- Why was maintenance skipped? No schedule existed.

- Why did no schedule exist? Nobody was assigned responsibility for preventive maintenance.

Actions taken:

- Created a monthly preventive maintenance schedule

- Assigned a dedicated maintenance in-charge

- Added a checklist for weekly machine inspections

Result: Breakdowns dropped by over 80% within three months, and stayed low.

This happened because they fixed the system, not just the machine. Five Whys Analysis completely transformed their production reliability.

When Should You Use Five Whys Analysis?

This tool is especially valuable when:

- Customer complaints are increasing — Understand why they keep happening, not just resolve them case by case.

- Defects keep repeating — Surface fixes are clearly not working.

- Safety incidents occur — True causes must be found to prevent serious accidents.

- Audit findings repeat — Same non-conformities appearing again means the real issue was never addressed.

- Deadlines are consistently missed — Dig into planning, resource, or communication gaps.

Five Whys Analysis works best for recurring, day-to-day operational problems where the real cause is hiding under the obvious one.

Common Mistakes That Reduce Its Effectiveness

Even with good intentions, businesses sometimes weaken their analysis:

- Stopping too early — The first obvious cause is rarely the real one. Keep asking.

- Blaming people — Focus on process gaps, not personal faults. Systems fail, not just individuals.

- Ignoring data — Base your answers on facts and evidence, not assumptions or gut feelings.

- No follow-through — Identifying causes without taking action wastes everyone’s time and trust.

Effective Five Whys Analysis always ends with concrete, verified improvements, not just a discussion.

What You Get from a Good Analysis

A well-executed session delivers:

- Clear identification of what actually caused the problem

- A practical action plan to prevent recurrence

- Stronger controls built into your daily processes

- Reduced failures as your systems improve over time

- Better decisions based on real understanding, not guesswork

It shifts your business from reactive firefighting to proactive problem prevention.

Conclusion

Five Whys Analysis is more than a problem-solving tool, it is a mindset that separates excellent businesses from average ones.

In competitive markets, recurring problems drain profits, frustrate customers, and exhaust your team. Finding and fixing the real underlying cause breaks this cycle. Problems get solved once, properly, permanently.

Does it take more effort upfront? Yes. Does it save time, money, and stress in the long run? Absolutely.

Start with one problem this week. Gather your team, ask “Why?” five times, and see what you discover.

Stop putting out the same fires. Find what is causing the smoke, and eliminate it at the source.

Image Credits: Performance

For more articles on startup growth, fundraising strategies, and business insights for Indian founders,

visit: Udyamee India Magazine