Why fixing failures is expensive, and how smart business owners use FMEA to prevent problems, protect profits, and build quality into every process from day one.

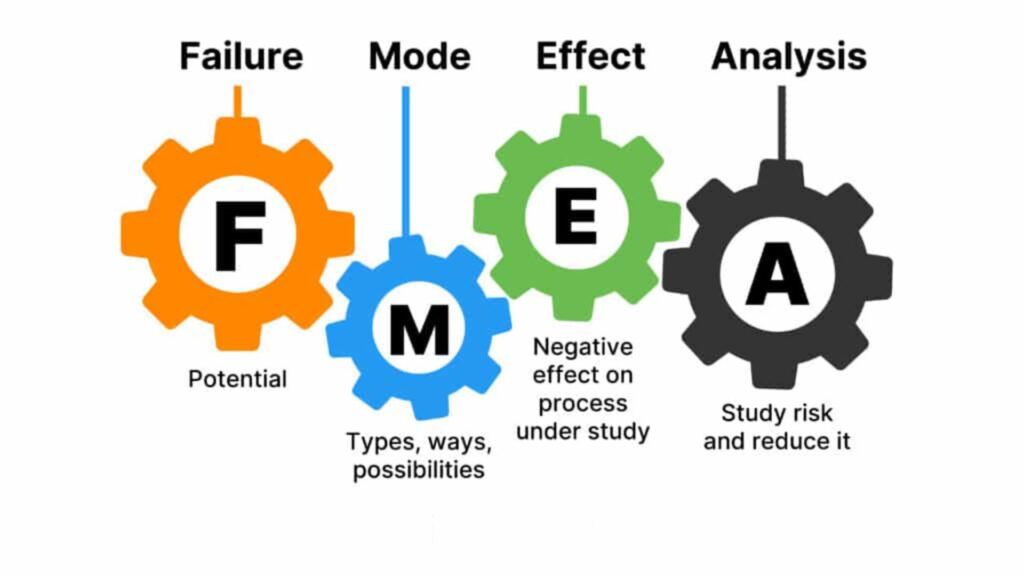

What Is FMEA?

FMEA stands for Failure Mode and Effects Analysis. It’s a structured method that helps you identify what can go wrong in your product, process, or system, before it actually goes wrong.

Think of it as asking four critical questions:

- What can fail?

- Why might it fail?

- What happens if it does fail?

- How can we prevent it?

This analysis is used across manufacturing plants, service businesses, healthcare facilities, construction projects, IT companies, and even small enterprises. The core idea is simple: think ahead instead of reacting after damage is done.

In India, where competition is fierce and margins are tight, preventing one major failure can save months of profit.

Why This Risk Analysis Matters for Indian Businesses

Whether you run a small manufacturing unit, a service business, or a growing company, FMEA delivers real value:

- Prevents costly mistakes – Catch problems during planning, not after production.

- Reduces waste and rework – Less scrap means lower costs and better efficiency.

- Improves quality consistently – Customers notice when things work right the first time.

- Protects your reputation – One major failure can damage years of trust.

- Supports ISO compliance – Quality management systems require risk-based thinking, and this method fits perfectly.

Instead of waiting for customer complaints to reveal problems, proactive analysis helps you act early. In business, prevention is always cheaper than correction.

How FMEA Works

FMEA examines three main elements:

- Failure Mode – What specific thing can fail? (A machine part breaking, incorrect data entry, delayed delivery)

- Effect – What happens if it fails? (Product doesn’t work, customer gets wrong order, production stops)

- Cause – Why does it fail? (Poor maintenance, unclear instructions, supplier quality issues)

After identifying these, your team evaluates each risk using three factors:

- Severity – How serious is the problem if it happens?

- Occurrence – How often is it likely to happen?

- Detection – Can we catch it before it reaches the customer?

These three scores multiply to create a Risk Priority Number (RPN). Higher numbers mean higher priority. This makes the analysis systematic and data-driven rather than based on gut feeling or guesswork.

Types of Failure Analysis

- Design FMEA (DFMEA) Used during product design. It helps identify weaknesses before manufacturing starts, reducing future warranty claims and product recalls.

- Process FMEA (PFMEA) Used to analyze manufacturing or service processes. For example, a textile unit might use this approach to identify problems in dyeing, stitching, or packaging processes.

- System FMEA Used for complex systems with multiple components. Common in automotive, engineering, and infrastructure projects.

A Real Example from Indian Business

Consider a small auto parts manufacturer supplying components to larger companies.

Using FMEA, the team identifies a potential problem:

Failure Mode: Incorrect hole diameter in the metal bracket

Effect: Part doesn’t fit during assembly at the customer site

Cause: Tool wear or wrong machine setting

Instead of waiting for rejection and returns, they take action:

- Schedule regular tool inspections

- Improve operator training on machine settings

- Add quality checks after drilling

Result? Reduced scrap, saved money, happier customers, and stronger reputation.

That’s the practical power of structured risk analysis.

When Should You Use FMEA?

FMEA is particularly useful when:

- Launching new products – Identify design risks before production starts.

- Starting new processes – Prevent problems in workflows from day one.

- Modifying existing systems – Understand what might break when you change things.

- Facing repeated complaints – Systematically find and fix root causes.

- Preparing for ISO audits – Demonstrate proactive risk management.

- Expanding operations – Scale smartly without multiplying problems.

The best time for this analysis is during planning stages, when changes are easier and cheaper to make.

Common Mistakes That Reduce Effectiveness

Even with good intentions, businesses sometimes undermine their risk analysis efforts:

- Treating it as paperwork – If it’s just for documentation, it won’t help.

- Working alone – One person’s perspective misses critical risks. Make it a team effort.

- Ignoring real data – Base your analysis on facts, not assumptions.

- Never updating it – Processes change. Your documentation should change too.

- Not taking action – Identifying risks without addressing them wastes everyone’s time.

The method creates value only when insights lead to concrete actions.

What You Get from Good FMEA

A well-executed FMEA delivers:

- Prioritized risk list – Know which problems need attention first.

- Clear action plan – Specific steps to prevent or reduce each risk.

- Stronger process controls – Built-in safeguards that catch problems early.

- Lower failure rates – Fewer defects, returns, and customer complaints.

- Better decisions – Confidence that comes from understanding your risks.

It becomes a living document that grows with your business, not a one-time exercise gathering dust.

Conclusion

FMEA is more than a quality tool, it’s a smart business practice that protects your bottom line.

In today’s competitive markets, even small mistakes can trigger major financial losses and damage hard-earned reputations. Structured risk analysis provides clarity and confidence when facing uncertainty.

Does it eliminate all risks? No. But it dramatically reduces them and gives you control over what happens next.

Businesses that focus on prevention consistently outperform those that rely on firefighting. They spend less on rework, keep customers happier, and build stronger reputations.

Whether you manufacture products, deliver services, or manage complex operations, FMEA helps you think ahead, act smart, and grow sustainably.

Start asking the right questions today: What can go wrong? Why might it happen? How can we prevent it?

That’s the power of proactive risk management. And it might be exactly what your business needs to stop problems before they start.

Image Credits: Reliability

For more articles on startup growth, fundraising strategies, and business insights for Indian founders,

visit: Udyamee India Magazine