Why confusion kills productivity, and how smart business owners use one powerful diagram to align teams, identify problems, and improve operations instantly.

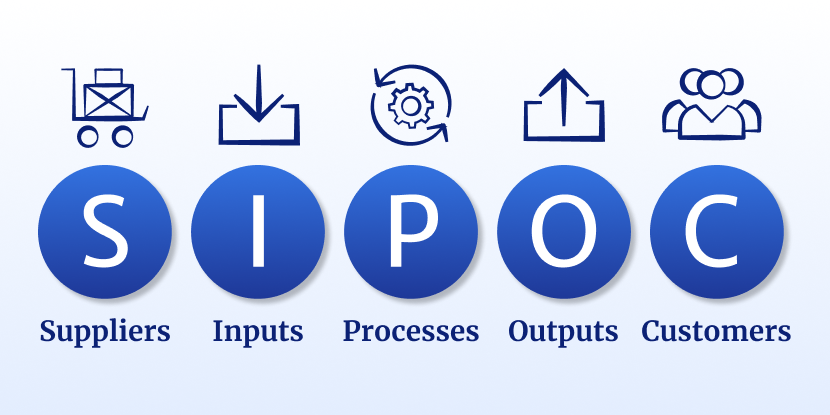

What Is SIPOC?

SIPOC is a simple tool that brings process clarity to your business operations. It stands for Supplier, Input, Process, Output, and Customer, the five essential elements that define any work process.

Think of it as a one-page snapshot that answers:

- Where does this process start?

- What does it need?

- What steps happen?

- What gets produced?

- Who receives the result?

Unlike complicated flowcharts, SIPOC focuses on the big picture without unnecessary complexity. This approach to process clarity helps teams understand the full picture quickly, and that understanding is where real improvement begins.

Why Process Clarity Matters for Indian Businesses

Many businesses struggle not because their work is complicated, but because process clarity is missing. When employees don’t know where a process starts, ends, or who’s responsible, problems follow.

The result? Duplicated work. Communication breakdowns. Blame games. Wasted time and money.

SIPOC addresses these issues by providing clear process understanding, defined boundaries, visible dependencies, team alignment, and a foundation for structured improvement.

For organizations following ISO quality standards, SIPOC naturally supports process management, risk thinking, and continuous improvement requirements.

The Five Elements Explained

- Suppliers provide the materials, information, or services needed to start the process, whether external vendors or internal departments like IT, HR, or finance.

- Inputs are what the process needs to function: physical materials, data, documents, approvals, or customer requirements. Clear inputs improve consistency and reduce mistakes.

- Process shows the main high-level steps, typically four to five, that convert inputs into outputs. Examples: receive order, check information, do the work, quality check, deliver to customer.

- Outputs are the final deliverables: finished products, approved reports, completed services, or verified data. Clear outputs ensure you produce what customers actually need.

- Customers receive the outputs. They can be external (buyers, clients) or internal (other departments, colleagues). Knowing your customers helps you focus on quality and timing.

When to Use SIPOC

SIPOC is particularly useful when mapping new processes, reviewing existing ones, starting improvement projects, preparing for audits or ISO certification, doing risk assessments, or fixing cross-department issues.

It’s often the first step before creating detailed flowcharts, a simple foundation for process clarity.

A Real Example from an Indian Business

Consider a customer service team in a software company wanting to improve response times. Using SIPOC, they create a one-page overview:

- Suppliers: Customers, technical team, helpdesk software

- Inputs: Customer complaints, product documentation, ticket history, support guidelines

- Process: Receive ticket → Assign to team member → Research response → Quality review → Send response

- Outputs: Solved ticket, customer confirmation, updated knowledge base

- Customers: End users, technical team (for escalations)

This brings immediate process clarity. The team realizes ticket assignment has no clear rules, causing delays. They also notice old ticket data isn’t easy to find, slowing research.

Without this structured mapping, these specific problems would remain hidden. Now the team can fix what’s actually broken instead of guessing.

Tips for Success

To get maximum value:

- Keep it simple – Four to five main steps only

- Work together – Complete SIPOC with team input

- Define boundaries clearly – Specific start and end points

- Include internal stakeholders – Other departments count too

- Don’t overcomplicate – Simplicity is the power

The goal is process clarity, not perfection.

Common Mistakes to Avoid

Teams often add too much detail, include too many steps, leave boundaries unclear, work alone instead of collaboratively, or forget internal departments.

SIPOC works when it provides process clarity and shared understanding, not when it becomes paperwork.

Results You Can Expect

Organizations using SIPOC experience better scope understanding, improved cross-department communication, stronger improvement foundations, easier ISO compliance, and less confusion and blame.

Most importantly, SIPOC builds a culture of process clarity. Teams stop assuming everyone “just knows” and start discussing processes openly.

Conclusion

SIPOC is a practical way to bring process clarity to your organization. In businesses where processes feel chaotic, this simple diagram provides the structure needed to move forward.

The beauty lies in its accessibility. You don’t need expensive software or consultants. You need a whiteboard, a diverse team, and commitment to understanding how work flows.

Start simple. Identify suppliers. Define inputs. Outline process steps. Clarify outputs. Know your customers.

That’s SIPOC. That’s process clarity at its most effective.

Whether you run a manufacturing unit in Rajkot, a service business in Bangalore, or a trading company in Mumbai, process clarity helps you work smarter, reduce waste, and serve customers better.

Image Credits: Consultport

For more articles on startup growth, fundraising strategies, and business insights for Indian founders,

visit: Udyamee India Magazine