Why waiting for major change is risky, and how smart business owners use continuous improvement to build quality, efficiency, and lasting competitive advantage.

What Is Kaizen?

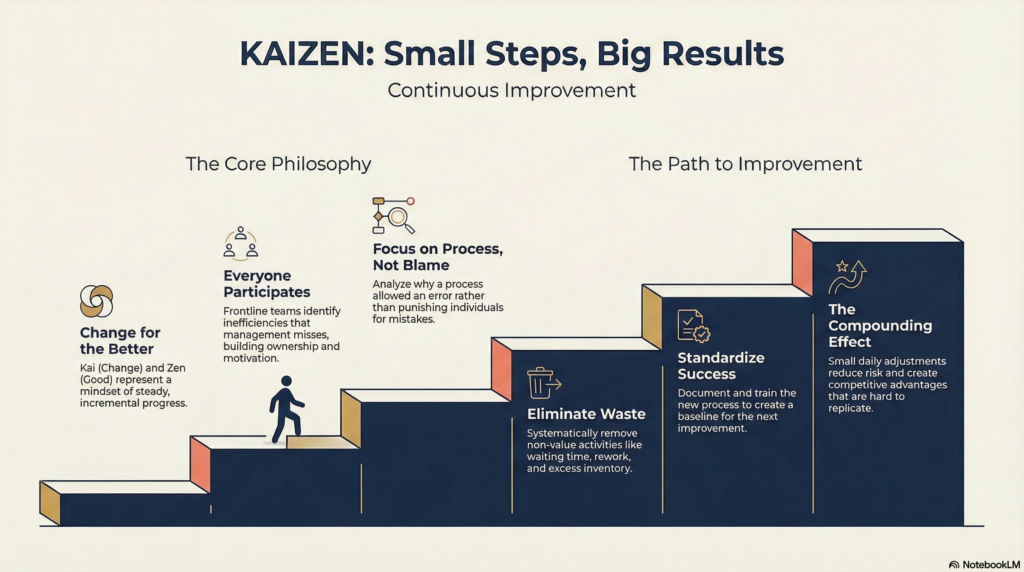

Kaizen is a Japanese philosophy built on a simple but powerful idea: continuous improvement made regularly by everyone in the organization creates extraordinary results over time.

The word itself tells the story. Kai means “change,” and Zen means “for the better.” Together, they represent a mindset that rejects waiting for big, expensive transformations and instead embraces steady, incremental progress.

Rather than launching major initiatives or investing heavily in dramatic overhauls, Kaizen encourages teams at every level to improve processes step by step. The result? Better quality, higher efficiency, lower costs, and stronger organizational performance, achieved through consistency, not disruption.

Kaizen is widely used in quality management systems and aligns naturally with ISO standards that emphasize continuous improvement as a core principle.

Why Continuous Improvement Matters for Your Business

In today’s competitive environment, standing still means falling behind. Markets shift, customer expectations rise, and new competitors emerge constantly. Organizations that fail to evolve risk losing relevance, or worse, losing customers.

Kaizen addresses this challenge by embedding continuous improvement into daily operations. Here’s what it delivers:

- Consistent quality improvement – Problems are addressed before they become crises.

- Waste reduction – Inefficiencies are identified and eliminated systematically.

- Employee engagement – Team members become active problem-solvers, not passive workers.

- Risk mitigation – Small, continuous adjustments reduce the likelihood of major failures.

- Cultural transformation – Improvement becomes everyone’s responsibility, not just management’s.

Because continuous improvement is part of daily work rather than a separate initiative, improvements become sustainable. They stick. They compound. And over time, they create competitive advantages that are difficult for others to replicate.

The Core Principles That Make Kaizen Work

Continuous Improvement as a Daily Practice

Kaizen rejects the notion that “good enough” exists. Every process, no matter how well it performs today, can be improved tomorrow. This mindset keeps organizations agile and responsive.

The focus is on small, manageable changes rather than sweeping transformations. These incremental improvements are easier to implement, less risky, and often deliver faster results than large-scale projects.

Everyone Participates

Kaizen recognizes a fundamental truth: the people who do the work understand it best. Frontline employees, operators, service staff—they see inefficiencies, bottlenecks, and opportunities that management often misses.

Examples of employee-driven improvements include:

- Operators suggesting better workflows

- Staff identifying recurring customer complaints

- Teams collaborating to solve quality issues

This approach builds ownership, motivation, and pride across all levels. When people know their voices matter, they invest more in the organization’s success.

Focus on Process, Not People

When something goes wrong, blame is easy. Kaizen takes a different path. Instead of pointing fingers at individuals, it asks: “What in the process allowed this to happen?”

This shift from blame to analysis creates psychological safety. Employees feel comfortable reporting problems and proposing solutions because they know they won’t be punished for speaking up. The result is honest feedback and meaningful, long-term improvements instead of quick fixes that mask deeper issues.

Eliminate Waste

Kaizen aims to remove activities that don’t add value to the customer or the organization. Common forms of waste include:

- Unnecessary movement or transportation

- Waiting time between process steps

- Rework caused by defects or errors

- Excess inventory sitting idle

Reducing waste improves both cost efficiency and quality. Resources are freed up to focus on value-creating activities, and customers receive better products or services at lower cost.

Standardize Success

Once an improvement works, Kaizen standardizes it. The new process is documented, communicated, and trained so that everyone follows the improved method consistently.

Standardization ensures that improvements are:

- Repeated reliably across teams

- Easy to teach to new employees

- Measurable for ongoing monitoring

Most importantly, standardization becomes the foundation for the next improvement. There’s always a clear baseline to build upon.

Kaizen and ISO: A Natural Partnership

If your organization follows ISO standards, whether for quality (ISO 9001), environment (ISO 14001), or other management systems, continuous improvement fits perfectly.

ISO requirements emphasize:

- Continual improvement

- Process approach

- Risk-based thinking

- Corrective and preventive actions

- Management review and learning

Kaizen supports all of these. In fact, many organizations resolve ISO nonconformities more effectively by adopting a continuous improvement mindset. Instead of treating audits as compliance exercises, they become opportunities for meaningful process improvement.

When and Where to Apply Continuous Improvement

Continuous improvement isn’t limited to manufacturing floors or large corporations. It works across industries and scales:

- In daily operations – Teams make small adjustments to workflows, communication, or service delivery.

- During quality issue resolution – Instead of firefighting, root causes are addressed systematically.

- After audits – Findings become improvement opportunities rather than just compliance checkboxes.

- In cost-reduction initiatives – Waste is eliminated without compromising quality.

- For customer satisfaction – Feedback loops are tightened, and service gaps are closed faster.

- As employee engagement programs – People feel valued when their improvement ideas are heard and implemented.

- Continuous improvement works in manufacturing plants, service organizations, healthcare facilities, educational institutions, and small and medium enterprises alike. The principles are universal.

A Real-World Example

Consider a service team that notices delays in responding to customer inquiries. Customers are frustrated, and the team feels overwhelmed.

Using Kaizen, they:

- Identify the delay cause (unclear responsibility for different types of inquiries)

- Make a small workflow change (assign inquiry types to specific team members)

- Track response times over two weeks

- Standardize the improved process once results are confirmed

No major investment. No expensive software. Just a thoughtful, small change that improves service quality immediately. Over time, this team will identify and implement additional improvements, compounding the benefits.

This is the power of continuous improvement.

Mistakes That Undermine Continuous Improvement

Even with the best intentions, organizations sometimes stumble. Common mistakes include:

- Treating it as a project – Continuous improvement isn’t a one-time initiative. It’s an ongoing practice.

- Expecting instant transformation – Big results come from accumulated small wins, not overnight miracles.

- Ignoring employee suggestions – If people’s ideas aren’t acted upon, they stop contributing.

- Failing to track improvements – Without measurement, it’s hard to know what’s working or justify continued effort.

- Skipping standardization – Improvements that aren’t standardized fade away when key people leave or priorities shift.

- Continuous improvement succeeds when it becomes a habit, embedded in how the organization operates every day, not an event or campaign.

The Results of a Strong Continuous Improvement Culture

Organizations that embrace continuous improvement experience tangible benefits:

- Better quality and consistency – Defects decrease, and customer satisfaction rises.

- Lower operational costs – Waste is eliminated, and efficiency improves.

- Higher employee engagement – People feel valued and motivated when they contribute to improvement.

- Improved customer satisfaction – Faster service, better products, and responsive problem-solving build loyalty.

- Stronger audit performance – Compliance becomes easier because processes are continually refined and documented.

But perhaps the most valuable result is cultural. Organizations develop resilience and adaptability. They become comfortable with change. They see problems as opportunities rather than threats. And they build momentum that competitors struggle to match.

Conclusion

Kaizen is more than a technique. It’s a way of thinking, a belief that improvement is always possible and everyone has a role to play.

In a world where change is constant and competition is fierce, waiting for major transformations is risky. Businesses that improve incrementally, consistently, and collectively position themselves to succeed not just today, but for years to come.

The beauty of continuous improvement lies in its simplicity. You don’t need massive budgets, external consultants, or complex systems. You need commitment, openness, and a willingness to take small steps forward every day.

Start small. Involve your team. Track your progress. Standardize what works. And repeat.

That’s Kaizen. And it might be exactly what your business needs to thrive.izen. It’s whether you can afford not to.

Image Credits: Created by NotebookLM

For more articles on startup growth, fundraising strategies, and business insights for Indian founders,

visit: Udyamee India Magazine