The brutal, costly realities of relying on one supplier, and how smart manufacturers protect themselves before it’s too late.

Introduction

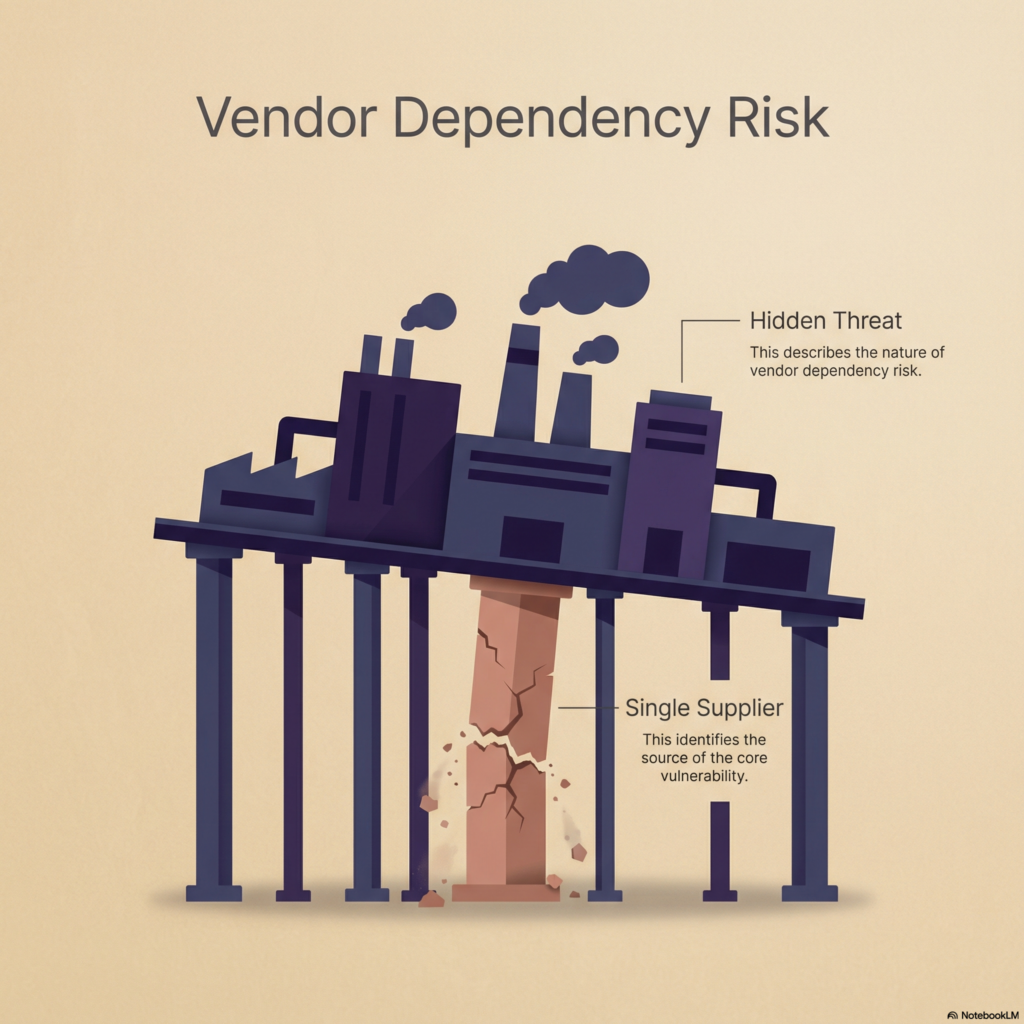

Vendor Dependency Risk is something most manufacturers ignore until it’s too late.

In many Indian manufacturing units, there is one sentence owners say with confidence:

“Woh supplier toh trusted hai.”

Until one day, that supplier delays delivery. Or shuts down. Or increases prices suddenly. Or fails a quality audit.

That’s when vendor dependency shows its real face.

A single supplier problem can stop production, delay dispatches, upset clients, and damage credibility. This is one of the most ignored yet dangerous threats in manufacturing businesses.

How Vendor Dependency Risk Slowly Builds

Dependency does not happen overnight. It builds slowly, quietly, and logically.

The supplier is reliable at first. Prices are good. Quality is stable. Communication is smooth. Over time, orders increase, alternatives are ignored, and backup suppliers disappear.

Before the owner realizes it, 60–80 percent of critical material comes from one source. This level of dependency feels convenient but is extremely risky.

Comfort creates blindness.

When One Supplier Controls Your Production

In manufacturing, some materials are critical. Without them, machines stop.

If that material comes from one supplier, the supplier indirectly controls your plant. Any delay, labour issue, transport problem, or regulatory trouble at their end becomes your problem.

This is where Vendor Dependency Risk turns from operational risk into business risk.

Production schedules fail. Client commitments break. Trust erodes.

Quality Failures Multiply Under Vendor Dependency Risk

When a single vendor supplies most inputs, quality issues become dangerous.

If one batch fails, there is no immediate alternative. Rejections increase. Rework costs rise. Dispatches get delayed. In regulated industries, audits may fail.

High dependency means you don’t just depend on supply, you depend on their discipline, systems, and ethics.

And you cannot control those fully.

Price Power Shifts When Dependency Is High

Initially, volume brings bargaining power. Later, dependency reverses that power.

The supplier knows you cannot switch easily. Prices creep up. Credit terms shrink. Negotiations become one-sided.

Margins suffer, but owners accept it to keep production running. This silent erosion damages long-term profitability and stability.

A dependent buyer is a weak buyer.

Compliance and Reputation Fall Victim to Vendor Dependency Risk

In today’s environment, vendor compliance matters.

If your supplier violates labour laws, environmental norms, or quality standards, your business may face consequences. Client audits don’t care whose fault it is.

High dependency increases compliance exposure because you are tied closely to another company’s behaviour.

One weak link can damage your brand, even if your internal systems are strong.

Growth Gets Stuck Due to Vendor Dependency Risk

Ironically, dependency blocks growth.

As demand increases, the same supplier may not scale at the same pace. Capacity limits, manpower shortages, or financial issues restrict supply.

Your business is ready to grow, but your supply chain is not.

This creates frustration and missed opportunities, all rooted in unchecked dependency.

Why Indian Manufacturers Avoid Reducing Vendor Dependency Risk

Many owners know this risk, yet avoid diversification.

Reasons are practical:

- Qualification costs

- Quality consistency fears

- Relationship comfort

- Fear of complexity

But avoiding alternatives increases risk, which is far more expensive when it breaks.

Backup planning feels unnecessary until it becomes urgent.

Reducing Vendor Dependency Risk Without Chaos

Reducing dependency does not mean replacing trusted suppliers. It means reducing risk.

Practical steps include:

- Developing at least one alternate vendor for critical materials

- Splitting volumes gradually, not suddenly

- Standardizing specifications to allow flexibility

- Auditing vendor capacity and compliance periodically

The goal is not disruption. The goal is resilience.

Conclusion

Vendor Dependency Risk is convenient, until it isn’t.

Many manufacturing plants don’t shut down due to lack of orders or poor products. They shut down because one supplier failed and there was no Plan B.

Managing this risk is not about mistrust. It’s about preparedness.

In manufacturing, control over supply is control over survival. And the businesses that recognize this early are the ones that stay standing when disruptions arrive.

Image credits: Created with NotebookLM

For more articles on startup growth, fundraising strategies, and business insights for Indian founders,

visit: Udyamee India Magazine