The brutal, hidden reasons behind the painful truth: “Profit hai, par paisa nahi hai”, and what smart manufacturers do differently.

Introduction

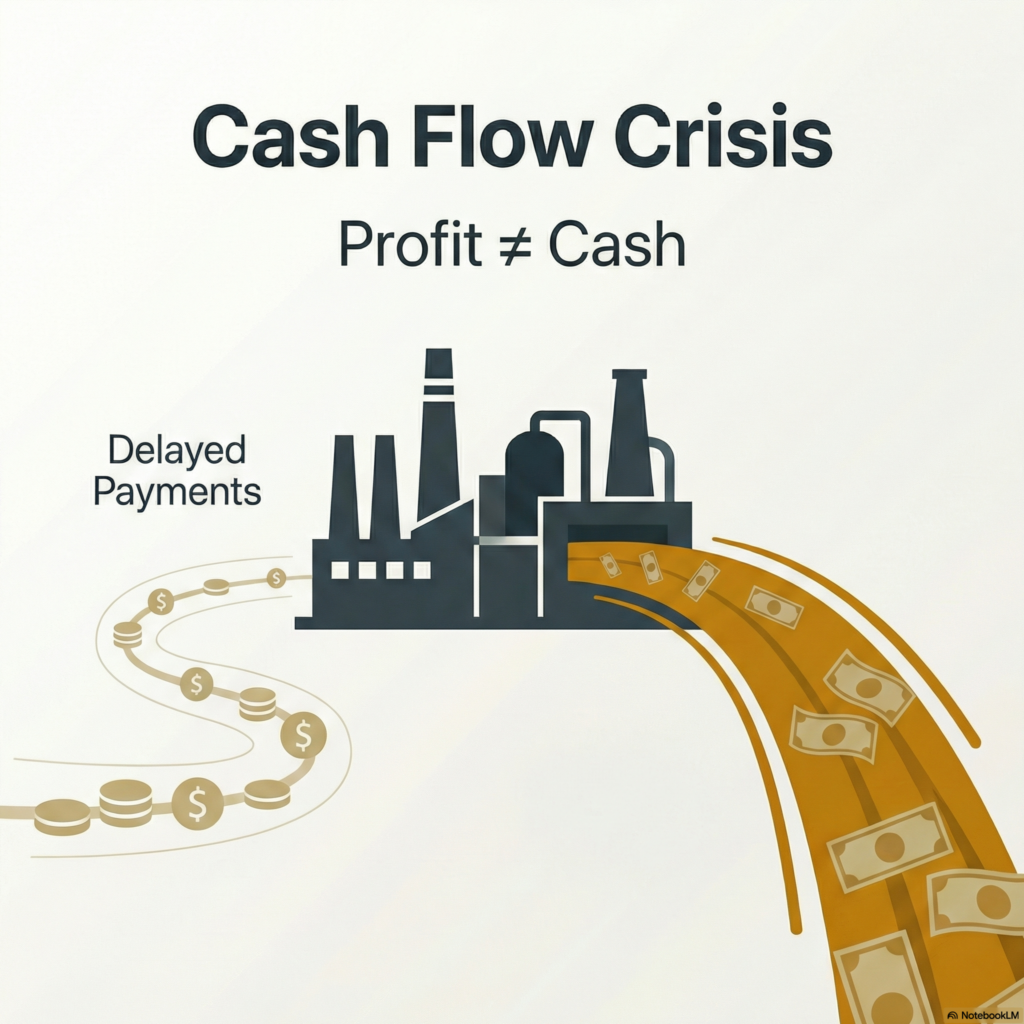

Cash Flow Crisis is something most Indian manufacturers face but rarely discuss openly.

In Indian manufacturing, one sentence is heard very often:

“Profit hai, par paisa nahi hai.”

This is not irony. This is reality.

Many manufacturing units show profits on paper but still struggle to pay salaries, vendors, or GST on time. Machines are running, orders are confirmed, and invoices are raised, yet the bank balance stays tight. This ongoing Cash Flow Crisis confuses and frustrates business owners.

Understanding why this happens is critical. Because a Cash Flow Crisis can shut down a profitable unit faster than losses ever will.

Long Payment Cycles Choke Cash Flow

Most manufacturing businesses work with 45, 60, or even 90-day payment terms. Big buyers demand credit, and small manufacturers agree just to keep orders coming.

On paper, sales look strong. In reality, money is stuck with customers.

Raw material suppliers want faster payments. Salaries are monthly. Electricity bills don’t wait. This mismatch creates constant Cash Flow Crisis pressure, even when the order book is full.

Profit comes later. Expenses come today.

High Inventory Triggers Cash Flow Crisis

Manufacturing needs inventory. Raw materials, work-in-progress, finished goods.

But excess inventory quietly kills cash flow.

Many units overstock raw materials due to price fears or supplier uncertainty. Finished goods pile up because dispatches are delayed or forecasts are wrong. All this money is locked, not working.

Inventory looks like an asset, but unmanaged inventory behaves like a liability and weakens Cash Flow Crisis month after month.

GST and Compliance Payments Drain Liquidity

GST has made compliance more transparent, but it has also increased cash flow stress for manufacturers.

GST is often paid before the customer clears the invoice. Input credits get delayed. Refunds take time. Meanwhile, cash goes out regularly.

For units operating on thin margins, these compliance payments create serious Cash Flow Crisis gaps, especially during expansion or seasonal demand.

Paper Profits Hide the Real Cash Flow Crisis

Many owners confuse accounting profit with real money.

Depreciation, receivables, stock valuation, and outstanding payments can show profits even when the bank account is empty. This false comfort delays corrective action.

When owners don’t track actual cash flow, decisions are made based on assumptions, not reality. This is when trouble builds quietly.

A business does not survive on profit statements. It survives on Cash Flow.

One or Two Clients Control the Money

In many manufacturing units, 50 percent or more revenue comes from one or two customers. When those customers delay payments, everything stops.

Salaries get postponed. Vendors get angry. Loans get stressed.

This dependency creates extreme Cash Flow Crisis risk. Even a short delay from one client can disrupt the entire operation.

Diversification is not only about growth. It’s also about protecting cash flow.

Expansion Without Financial Readiness

Growth excites founders. New machines, new sheds, new staff.

But expansion demands upfront money. Machines don’t pay immediately. New orders take time. Fixed costs increase instantly.

Without proper planning, expansion multiplies Cash Flow Crisis problems. Many profitable units collapse during growth phases, not during slow periods.

Strong cash flow planning should come before expansion, not after.

No Clear Cash Flow Monitoring System

Many manufacturing businesses track production and sales daily but review cash flow only when problems arise.

No weekly cash review. No receivable ageing discipline. No clear inflow-outflow planning.

Without visibility, owners react late. And late reactions are expensive.

Monitoring Cash Flow is not a finance team job alone. It’s a survival habit.

Conclusion

Profit feels good. But Cash Flow keeps the factory lights on.

Most manufacturing units don’t fail because their product is bad or demand is low. They fail because money gets stuck, delayed, or mismanaged.

Understanding and controlling cash flow is not about being conservative. It’s about being realistic.

Factories shut down quietly, not suddenly. And in most cases, the warning signs were visible in the cash flow long before the crisis arrived.

Image credits: Created with NotebookLM

For more articles on startup growth, fundraising strategies, and business insights for Indian founders,

visit: Udyamee India Magazine